OUR HISTORY

From his early days working in his grandfather's machine shop as a young teenager, Mark Hess was destined to own his own tool and die business. Before founding Hess Industries, Mark spent fourteen years honing his skills and expertise at various companies. During this time, he gained valuable experience in building and repairing progressive and transfer dies, managing teams, production scheduling, and quality control. Mark also completed an extensive apprenticeship program, overseeing all aspects of the design, build, repair, and operation of hundreds of dies in a production setting. Mark also earned an Associate Degree in Mechanical Engineering, graduating with honors from North Central State College.

JUNE 1999

Mark and his wife Pam founded Hess Industries, Ltd. as a sole proprietorship. The company began with a single account, but within months, they had added several more customers. Operating out of 1,800 square feet of space leased from Braintree, Hess Industries established its roots at 201 East 5th Street in Mansfield, serving customers throughout central Ohio.

2000

The business continued to grow and additional employees were added throughout the year. Hess Industries purchased their first two CNC Machines (Computer Numerical Control Machines), a Wire EDM (Electronic Discharge Machine) and a Machining Center. By March, the company had outgrown its initial space and expanded to over 3,800 square feet at the Mansfield Incubator.

2001

The greater Mansfield business community recognized Hess Industries' success by naming them the Mansfield Chamber of Commerce's Small Business of the Year for 2001.

2001

Due to growing demands, Hess Industries purchased their second Wire EDM machine. That same year they also acquired a larger CNC Machining Center to handle more extensive details.

2002

The company invested in new 3D software, Virtual Gibbs and Solid Edge, enabling them to maintain tight tolerances and manufacture complex parts using solid modeling technologies. As pioneers in adopting these cutting-edge technologies, they laid the foundation for the company's continued success, which remains integral to their operations today.

2003

Pioneer Career and Technology Center honored both Mark and Pam Hess for their outstanding achievements by presenting them with the Distinguished Alumni Award.

2004

To further support its expanding EDM business, Hess Industries acquired an EDM Hole Popper.Additionally, they invested in a Clearing 250-ton straight-side press, enabling them to conduct in-house die trials and proving processes for every tool manufactured by Hess Industries.

2005

Mark was honored with induction into the North Central Ohio Entrepreneurial Hall of Fame.

2005

Hess Industries solidified its position as a leader in the region by acquiring its third Wire EDM machine, distinguishing itself with one of the largest Wire EDM departments in the area. Additionally, they expanded their capabilities by adding another larger CNC Machining Center to accommodate the growing demands of the business. These strategic investments not only increased capacity to better serve customers but also facilitated expansion into new markets and industries.

2008

Hess Industries acquired its first CNC Turning Center to meet the growing demand for turning services from new customers.

2009

Mark and Hess Industries were honored as Outstanding Business Partners for their longstanding dedication and contributions to the Precision Machining Advisory Board at Pioneer Career and Technology Center.

2011-2012

Drawing from their extensive experience and expertise in building progressive and transfer dies, Hess Industries teamed up with Hutchison Tool Sales to revolutionize their offerings. Through a comprehensive redesign process, they now provide a complete line of in-die tapping units, which are distributed to tool and die facilities worldwide

2015

To meet the increasing demands of their in-die tapping business, Hess Industries invested in their second CNC Turning Center.

2016

Hess Industries made a significant move by acquiring an existing building in the Mansfield Industrial Park at 108 Sawyer Parkway. Throughout the summer, they undertook extensive renovations of the entire building. By November, the company had successfully transitioned to its new space. The facility spans 15,000 square feet and occupies 18 acres of land, providing ample room for future expansion.

2017-2018

Hess Industries further solidified its position as the leader in the wire EDM arena by acquiring its 5th and 6th Wire EDM Machines.

2018

Hess Industries purchases its first Turning Center with Live Tooling. This allows them to turn and mill on the same machine helping them be more efficient on parts that require both.

2019

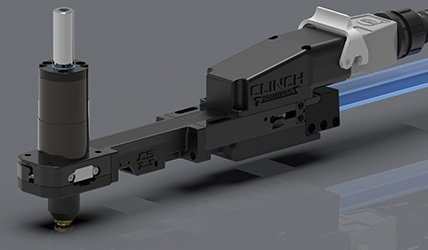

Hess Industries started designing and building their Clinch In-Die Nut and Stud Insertion Tooling. The In-Die Fastener setting systems can be used with both transfer and progressive dies.

2019

Hess purchased two MarkForged 3D printers that print with carbon fiber. These are industrial 3D printers that print continuous carbon fiber for industrial strength parts. These printers are designed for 24/7 lights out manufacturing. Hess has produced many fixtures, gages and even production parts with their printers. The purchase of these units have helped them land many new jobs as they are able to rapidly prototype parts that would have taken months to make conventionally.

2019

Richland area business community recognized Hess' success by naming Hess Industries Ltd. the winner of the Richland Area Chamber of Commerce's Small Business of the Year for 2019.

2020

Hess Industries took a significant step into the world of 5-axis machining by purchasing a VF4 with a 5-Axis Trunnion. Leveraging the slowdown period during Covid, they dedicated themselves to mastering this cutting-edge technology. Additionally, they upgraded their Gibbs-CAM software to augment their programming capabilities. These advancements have empowered them to manufacture their most complex parts with greater efficiency and precision, significantly reducing production time.

2020

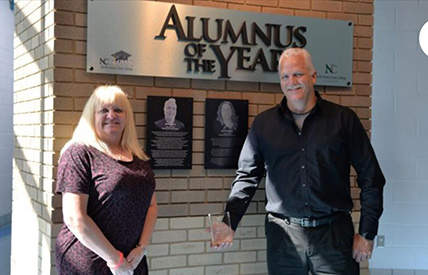

The North Central State College community honored Mark's success by naming him the 2020 Alumnus of the Year. He was only the second recipient of this award since its inception.

2020-2021

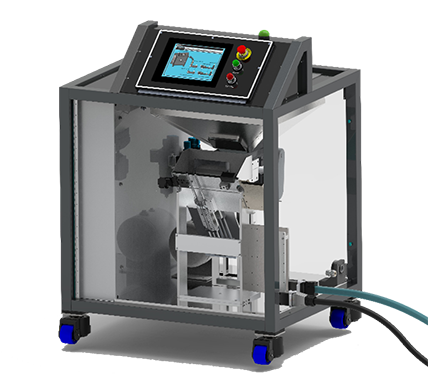

Hess Industries developed and built their first Clinch Solutions Feed System to complement the Clinch In-Die Nut and Stud Insertion Tooling introduced in 2019. Making them one of two manufactures in the world that make both In-Die Tapping and In-Die Clinch systems.

2021

In its 22nd year of operation, Hess Industries welcomed Ryan and Haley Hess as co-owners, marking a new chapter in the company's leadership. As evident from the title picture of this page, Ryan was just 5 years old when he helped his dad assemble the first die.

2022

Hess Industries acquired twin UR-10e robots and built their first robotic cell to assist a customer in need. This innovative solution not only resolved the immediate issue, but also showcased Hess Industries' commitment to leveraging advanced technology to continue producing high-tech tooling solutions.

2023

Hess Industries has expanded its capabilities with an entire print farm, including ten Markforged 3D printers. Out of necessity, they also designed and built the MegaDryPro, which they now sell through Markforged resellers to fellow users. This development highlights their innovative spirit and commitment to meeting both internal needs and industry demands.

2024

Team Hess acquired its first LightWELD® Handheld Laser Welder. This advanced laser welding technology enables them to make faster welds while consistently producing high-quality results for their products. In addition to acquiring the LightWELD® Handheld Laser Welder, Team Hess constructed a dedicated laser room to ensure safe and efficient welding operations.

From the beginning and until present day, the Hess team have set themselves apart from its competitors by being a leader in adopting the latest technology and acquiring the most sophisticated equipment on the market.

Hess Industries has consistently gained customers and increased its business by focusing on exceptional customer service. Customers who need high-tech tooling solutions value Hess' quality services and rewarded Hess Industries with continual increased sales since our inception. Through God's grace, the history of Hess Industries continues to be written every day.